Rabotti

CRS200

The new Rabotti CRS200 bench is the result of the long experience gained by the Rabotti staff at the service of modern repair workshops for Diesel injection systems.

It features a modern and lighter structure with particular attention to the convenience of installing pumps and injectors to be tested while preserving the historical strengths of the Rabotti benches such as reliability, ease of use, the breadth of the database and the accuracy of our shot-to-shot measurement system (“Cylinder”) which is widely recognized by the market by now.

Highlights

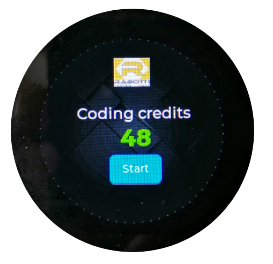

“Pay as you go”

coding

Our Pay As You Go model provides flexible, cost-efficient injector coding—purchase credits only for the coding operations you need. No upfront fees, no wasted licenses—just scalable, on-demand access to coding for all major injector brands.

Indra Software

Rabotti’s Indra Software is the advanced control system powering our test benches, offering precise real-time monitoring, automated diagnostics, and customizable testing for fuel injectors, pumps, and more. With an intuitive interface and multi-brand compatibility, it ensures accurate, efficient performance validation.

Features and

characteristics

IMA Coding for Bosch Solenoid injectors (CRI2)

IMA 6/10 characters for Heavy Duty Bosch injectors (CRIN)

ISA 7/10 characters for Piezoelectric Bosch injectors (CRI3)

Test of Dual Coil Bosch Injectors (CRIN4.2)

C2I/C3I/C4I coding for DFI1-DFI1.5 and DFI1.20 Delphi injectors

16/22/24/26/30 characters coding for Denso Injectors

Integrated Pressure Sensor check for Denso i-ART injectors

6 characters coding for Siemens/VDO injectors

Large Diesel Engine Injectors Test (“LDE” such as L’Orange)

Bosch CP1/CP3/CP4 CR pump test

Delphi DFP1, DFP3, DFP4, DFP6, DFP7 pump test

Denso HP3, HP4 pump test (Integrated NTC sensor check)

Siemens/VDO CR pump test

Synchronized Denso HP5 pump test

Synchronized Bosch CP4E pump test

Download

area

Technical sheet

CRS200

Download product image

HIGH RESOLUTION